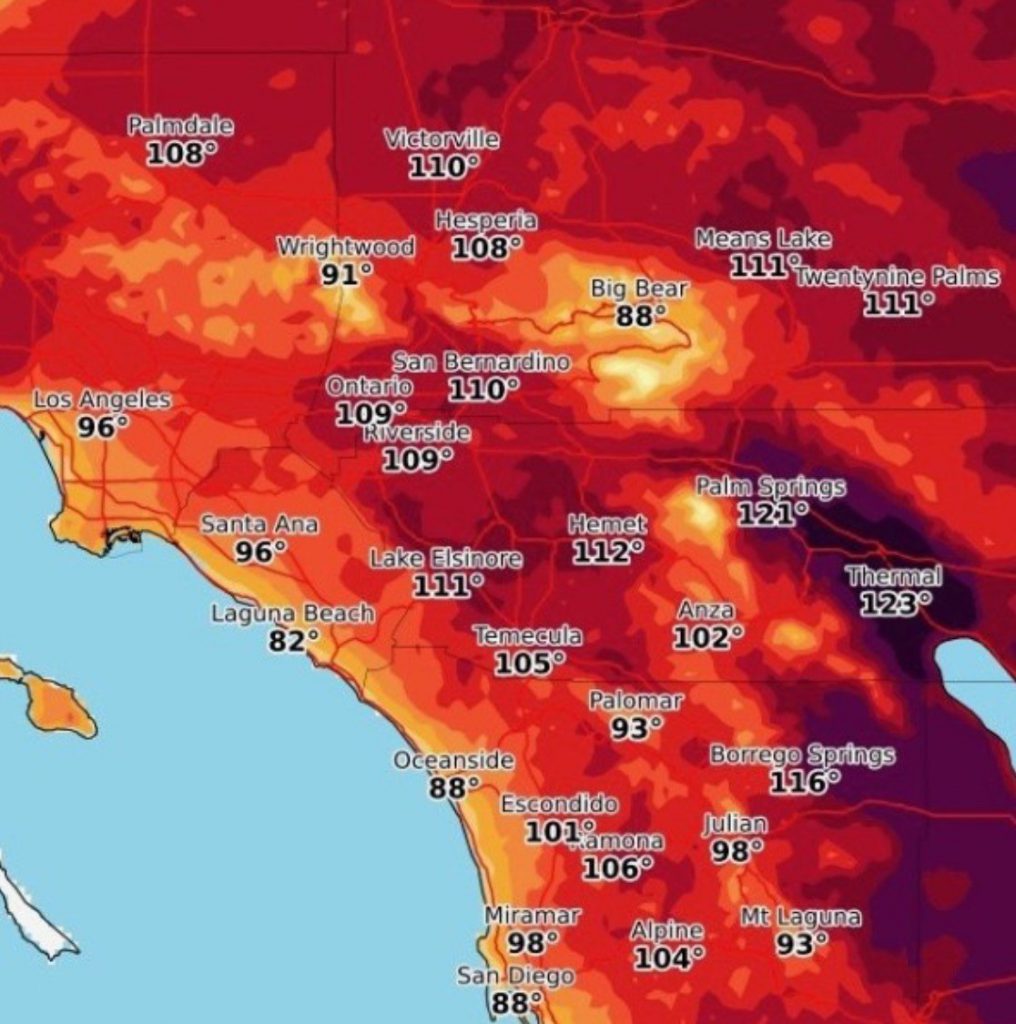

Historic heat records fell in California earlier this month. Yet, two weeks later, another mass of warm air has returned to the southern part of the state, heating the region for days.

The second heat wave of July will last from Monday through Thursday, said the National Weather Service. While this heat won’t be quite as severe as the last, it’ll still bring “record and near-record high temperatures” to different areas of California.

As average temperatures around the globe continue their accelerated rise, extreme heat events like these are becoming more and more frequent.

“The big picture is clear,” Daniel Swain, a climate scientist at the Institute of the Environment and Sustainability at the University of California, Los Angeles, said in an interview.

“As our temperatures globally have been increasing, we’ve been seeing a lot more record-breaking heat waves,” said Swain. “It’s not just this year or last year — it just the way things have been.”

Potent greenhouse gases amassing in Earth’s atmosphere, notably carbon dioxide, are responsible for trapping heat on the planet, causing overall temperatures to rise.

“With greenhouse-gas induced warming temperatures, heatwaves are expected to become more common,” Robert Weisenmiller, Chair of the California Energy Commission, said via email.

“The number and duration of heat waves will also increase and, again, high temperature records will be broken more frequently,” said Weisenmiller.

“There are many variables with weather, but scientist around the world agree, in general, extreme weather is becoming more common, along with rising seas, prolonged droughts, and more frequent wildfires.”

The region of warm air now over Southern California, often referred to as a “heat dome,” had been parked over the desert Southwest, but Swain noted that it can “wobble around.” Now, it’s come back west.

It’s not unusual for inland Southern California, like the valleys beyond Los Angeles, to hit 110 degrees Fahrenheit or higher during a heat wave. But, “it’s something special to get those temperatures near the coast,” said Swain, as they did earlier this month. Temperatures here are usually tempered by the cooler air over the Pacific Ocean.

“A warming of our planet and of California in particular will result in more frequent breaks of temperature records including areas near the coast,” said Weisenmiller. “Both coastal areas and inland regions will experience record breaking temperatures in both regions.”

The University of California, Los Angeles campus, for instance, hit 111 degrees on July 6 — an all-time record. These extreme temperatures were largely enabled by wind blowing air down from the warm air mass hovering thousands of feet above Southern California. As warm air descends, it compresses, generating even more heat.

“When you warm something up that’s already warm, it can become super hot,” said Swain. At 3 a.m. in coastal Santa Barbara County, it was nearly 100 degrees Fahrenheit on July 6.

The new heat wave, while less intense than the previous scorcher, will reach between 100 and 110 degrees in Southern California’s valleys and deserts. The heat isn’t just restricted to California, as temperatures in Phoenix, Arizona are forecast to reach over 115 degrees Fahrenheit this week.

In California, perhaps few all-time records will fall this week. But others likely will.

“We’re probably going to have record-high temps — merely exceeding the daily records,” said Swain.